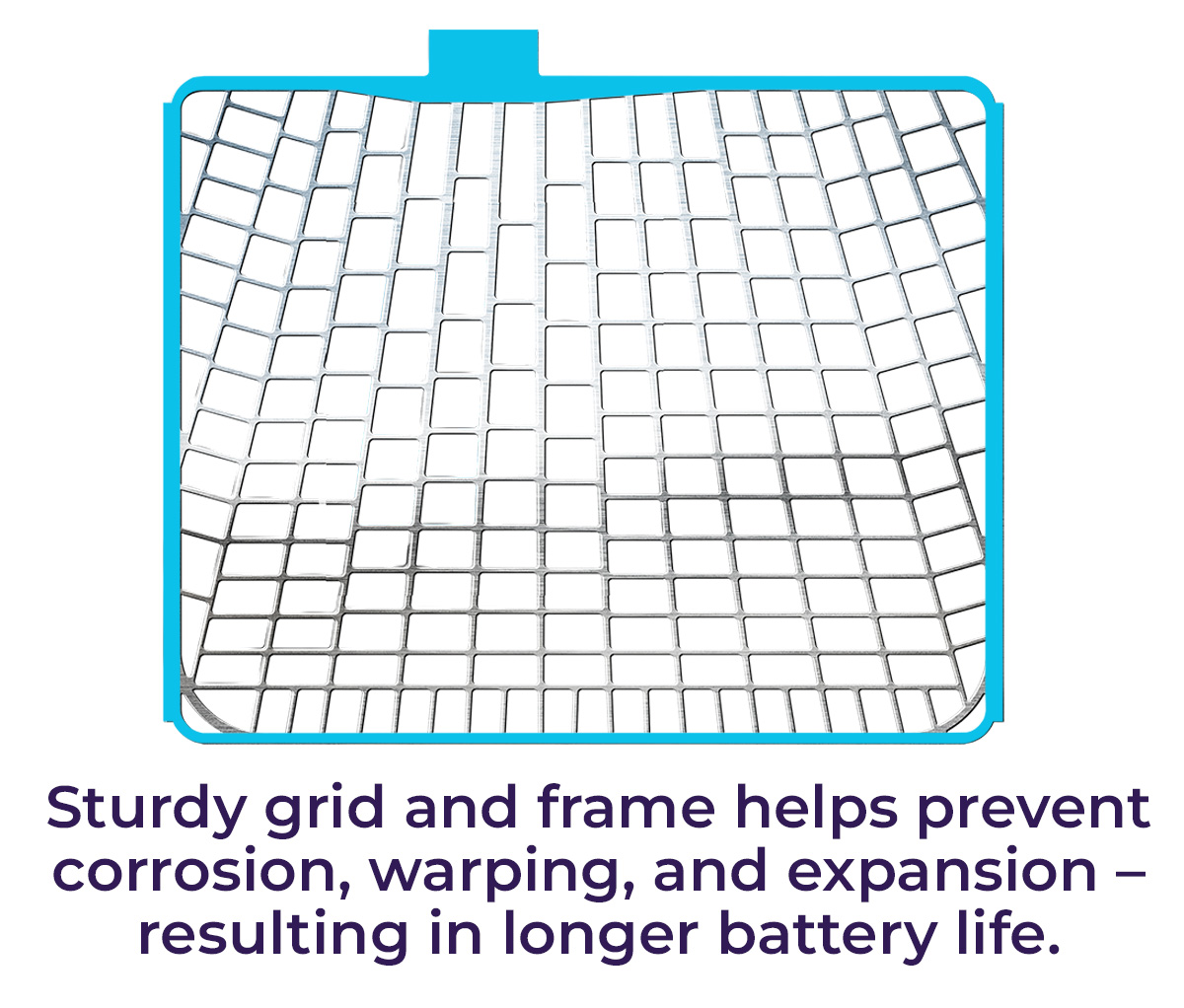

PowerFrame® Grid: Built for Strength and Reliability

Trusted technology that powers today’s vehicles with confidence

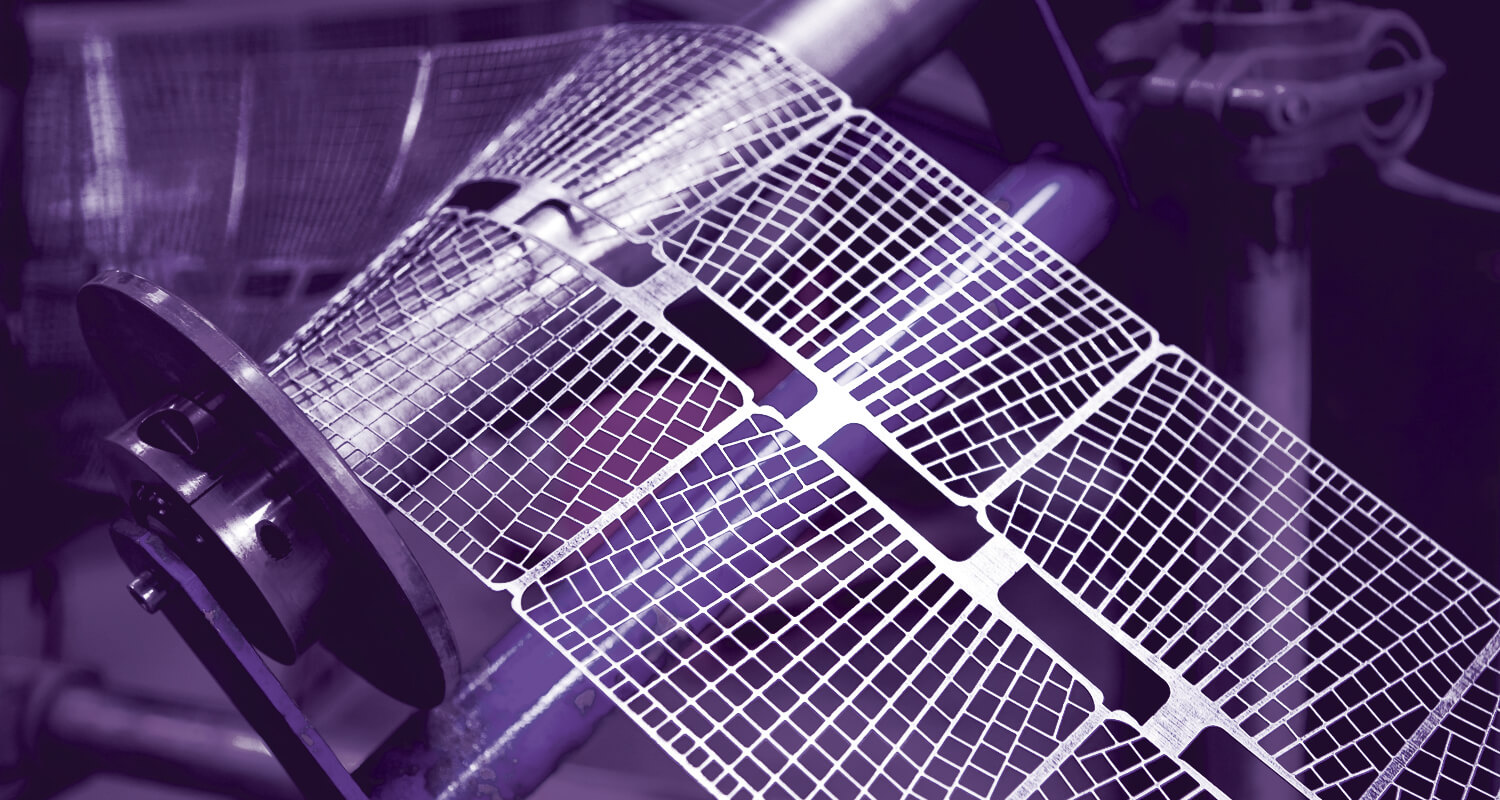

What Is PowerFrame® Technology?

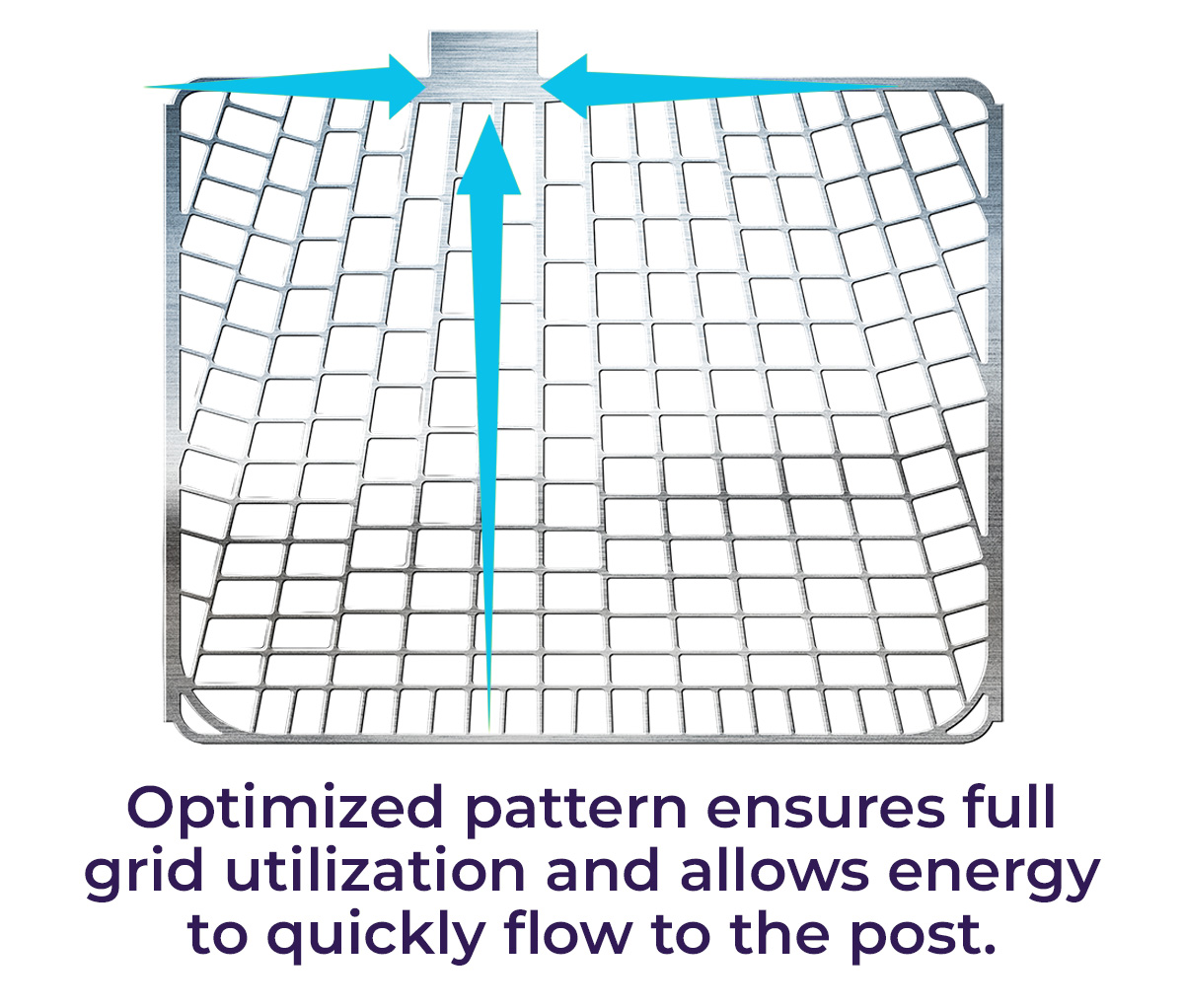

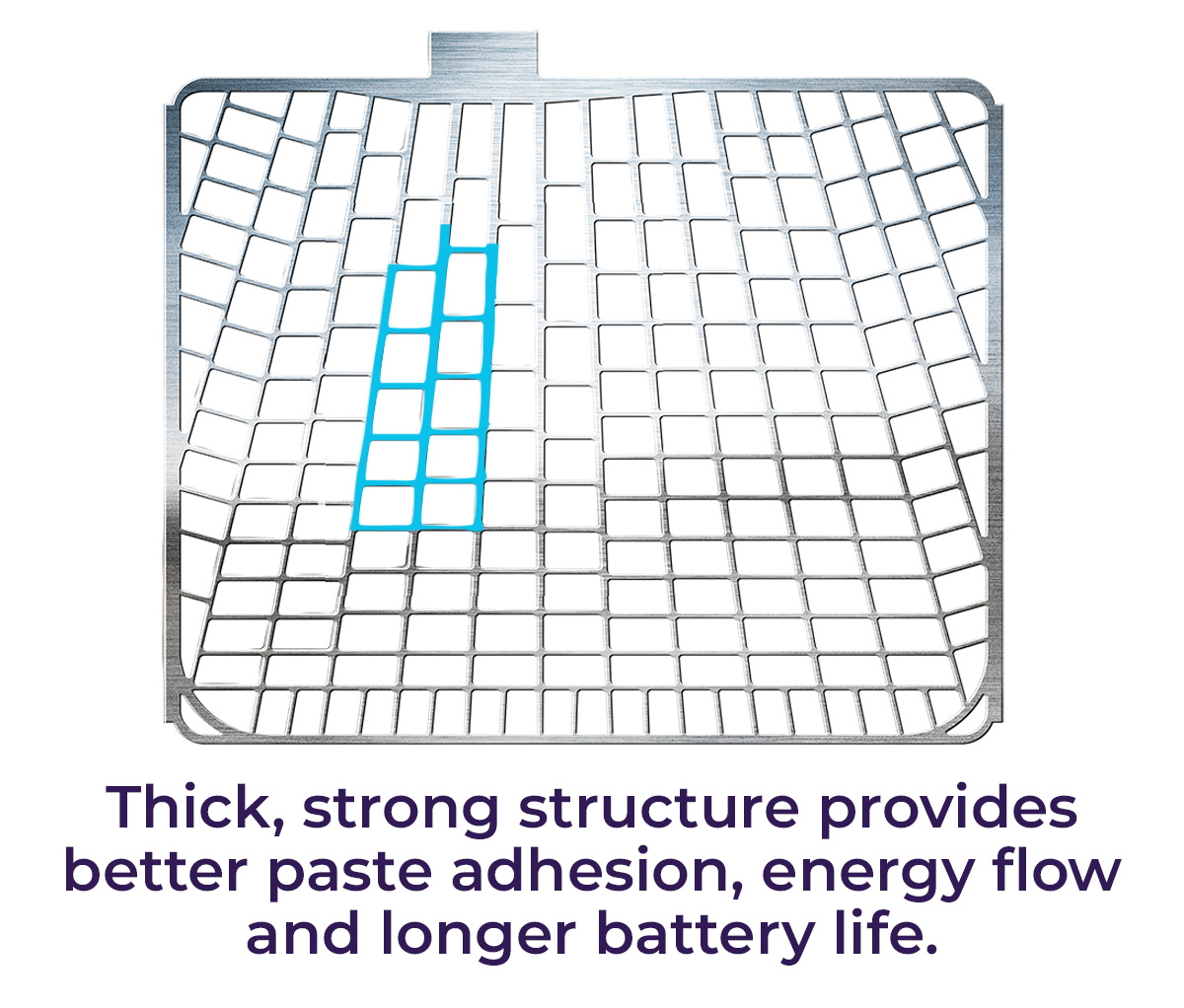

PowerFrame® grid technology from Clarios is a patented stamped design that reinforces the battery's internal structure. Unlike traditional cast grids, PowerFrame delivers stronger, more consistent performance.

Why it matters: Modern vehicles demand more power. PowerFrame helps your battery meet the challenge.

Four Reasons to Trust PowerFrame®

Engineered for Modern Demands

Today’s vehicles include features like advanced infotainment systems, premium lighting, and start-stop technology. PowerFrame’s stamped grid design evenly distributes current and resists wear, extending battery life under pressure.

See the Difference

Corrosion Resistance

Traditional: Lower

Electrical Flow

Traditional: Less optimized

Environmental Impact

Traditional: Higher carbon footprint

Durability

Traditional: More prone to failure

Smarter Manufacturing, Cleaner Future

PowerFrame® technology isn’t just tough—it’s environmentally conscious. Its precision-stamped grid uses less raw material, cuts down on waste, and supports cleaner energy solutions.

FAQs

- What makes PowerFrame® different?

It’s stamped, not cast—providing consistent strength and electrical flow. - Is it available in all batteries?

PowerFrame® is used in premium batteries from Clarios-supported brands. - How does it support sustainability?

It uses less energy and produces fewer emissions during manufacturing.